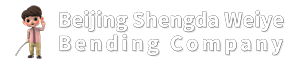

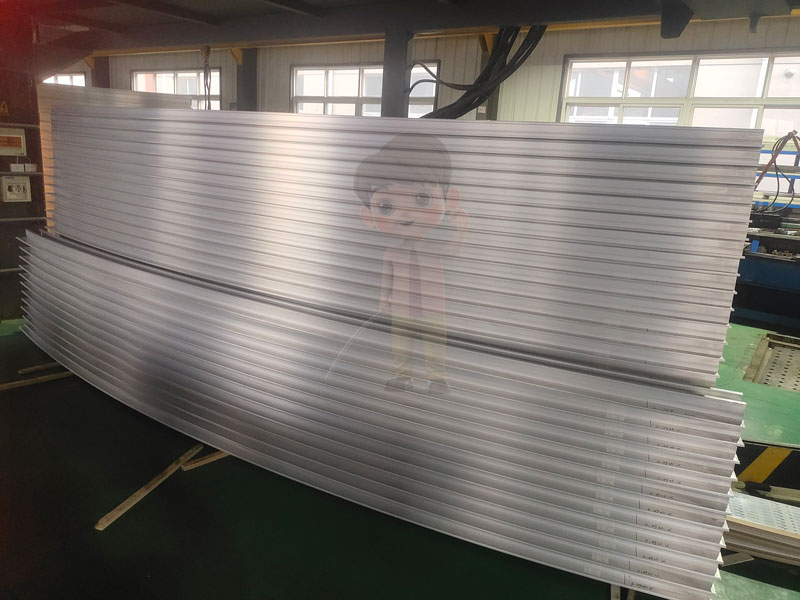

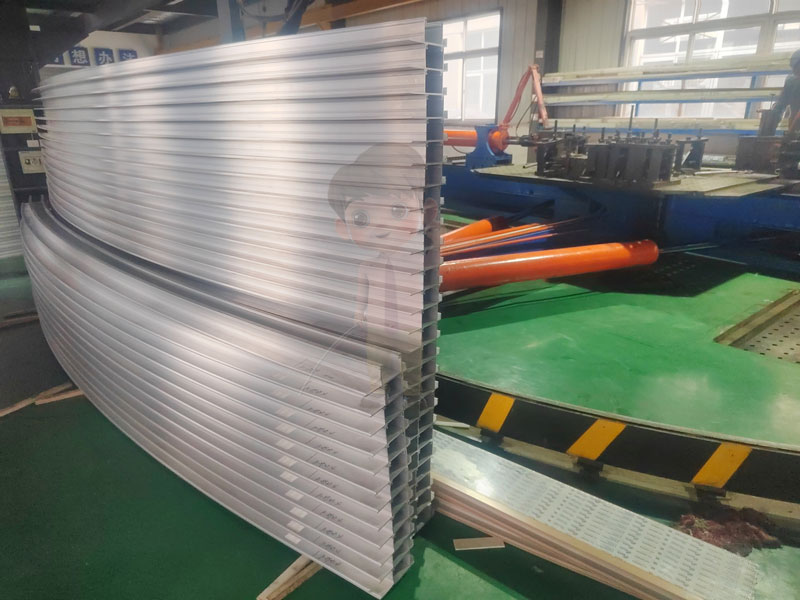

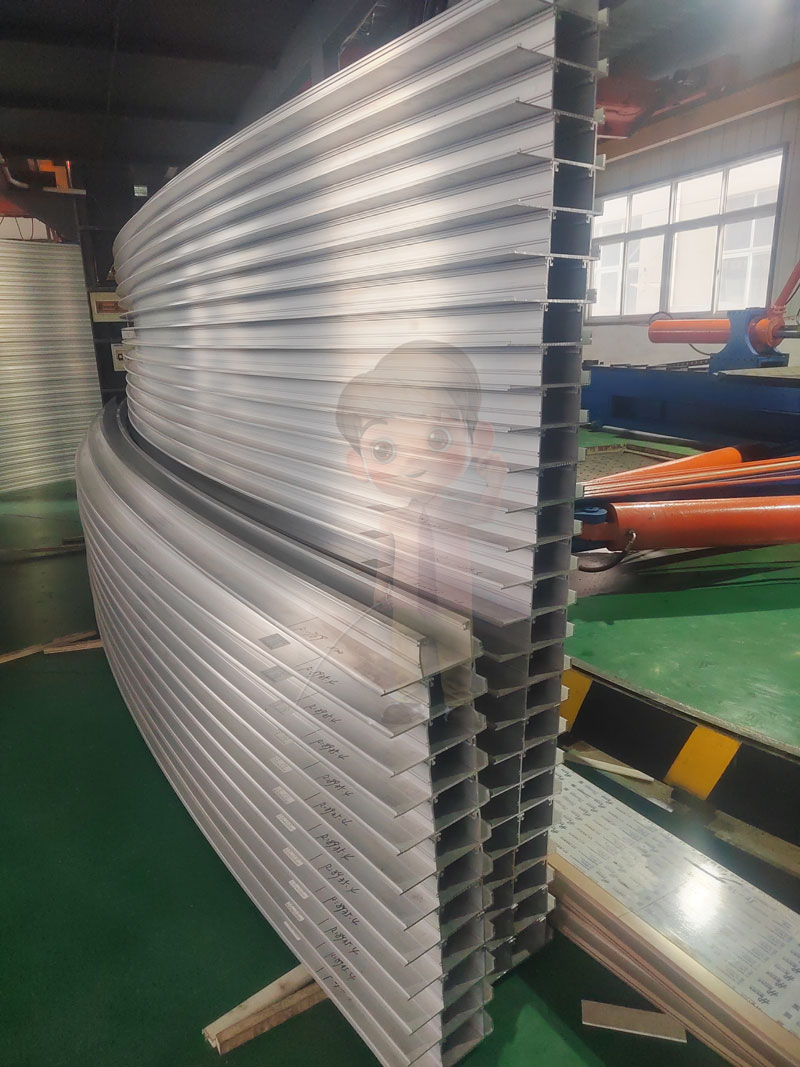

Unit type curtain profile bending

The following are the basic steps for bending unit curtain wall profiles:

Preparation work: Prepare profiles and bending equipment according to design requirements, check the working status of the equipment, and ensure its normal operation.

Fixed profile: Fix the profile onto the fixture of the bending equipment to ensure its stability.

Set parameters: Set parameters such as bending radius, angle, and tensile force according to design requirements.

Bending operation: Start the equipment and use mechanical devices to stretch and bend the profile into the desired shape.

Inspection and adjustment: After completing the bending process, inspect the profile to ensure it meets the design requirements. If there is a deviation, make appropriate adjustments.

Post processing: Perform necessary post-processing on the bent profile, such as cutting, polishing, and surface treatment.

Precautions for using this bending product

Material selection: Select profiles suitable for the bending process, such as aluminum alloy, steel, etc., to ensure that the material has good ductility and strength.

Equipment maintenance: Regularly inspect and maintain the bending equipment to ensure its normal operation and avoid production interruptions or quality issues caused by equipment failures.

Operating standards: Operators must undergo professional training and strictly follow the operating standards to avoid safety accidents or quality issues caused by improper operation.

Quality control: Establish a comprehensive quality control system and conduct strict inspections on each batch of products to ensure they meet design and usage requirements.

The application of stretch bending technology in modular curtain walls is very extensive, especially in the following scenarios:

Curved curtain wall: A common curved or curved curtain wall in modern architecture that requires the use of stretch bending technology.

Special shapes: Some complex building facade designs, such as wavy and spiral shapes, require precise bending techniques to achieve.

Large span glass walls: Some large-span glass curtain walls also require the use of tensile bending technology to process the profiles in order to enhance structural stability and aesthetics.

The fine bending processing technology provided by Tianjin Shengda Hongye Technology Co., Ltd. plays an important role in the production process of modular curtain walls. It not only improves production efficiency but also ensures product quality, providing more possibilities for modern architectural design.

Leave us a message

English

English Chinese

Chinese Japan

Japan German

German

LIST

LIST