Industrial special profile bending

Industrial metal material processing

Industrial metal material bending is a process of processing industrial metals into specific shapes through stretching and bending. This process is commonly used for structural components in manufacturing fields such as railway locomotives, automobile manufacturing, other transportation equipment, ships, textiles, chemicals, etc.

Industrial metal material bending application

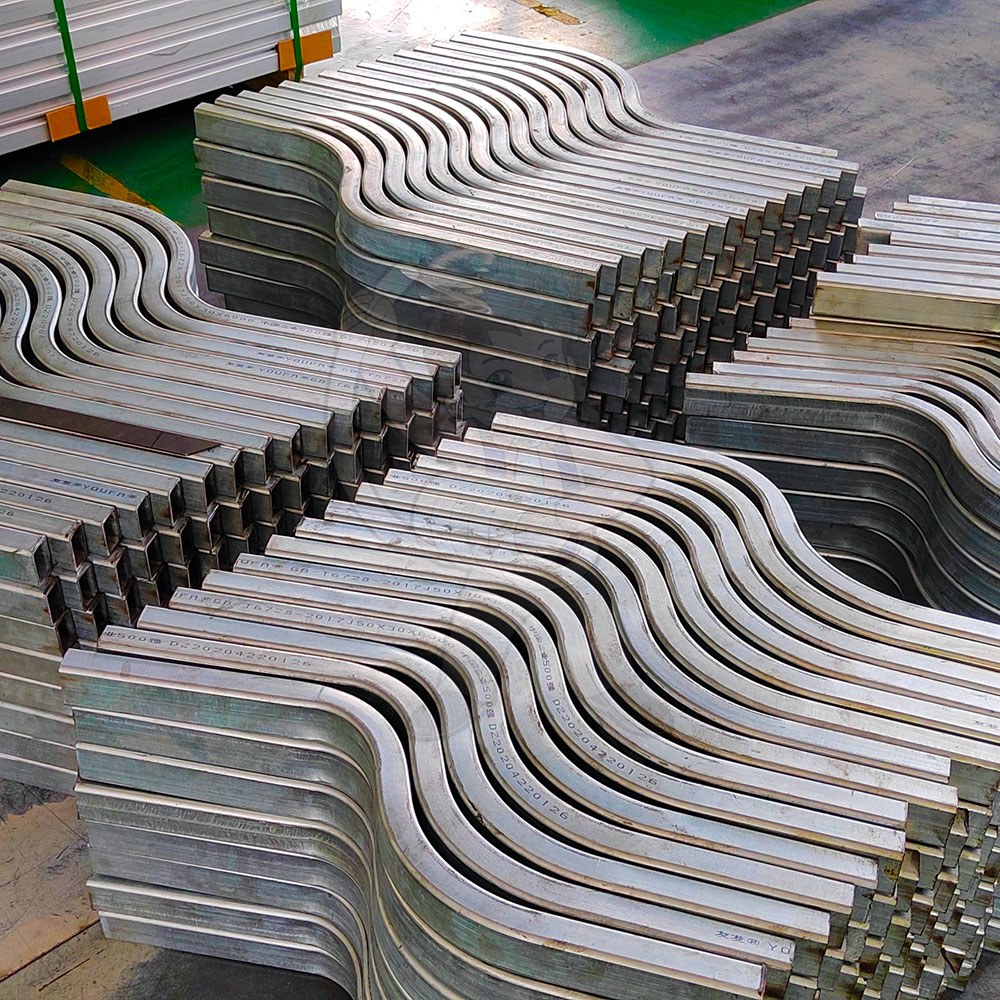

Railway locomotive1. Roof curved beams (made of iron, aluminum, or stainless steel) for high-speed trains, conventional trains, and other types of trains

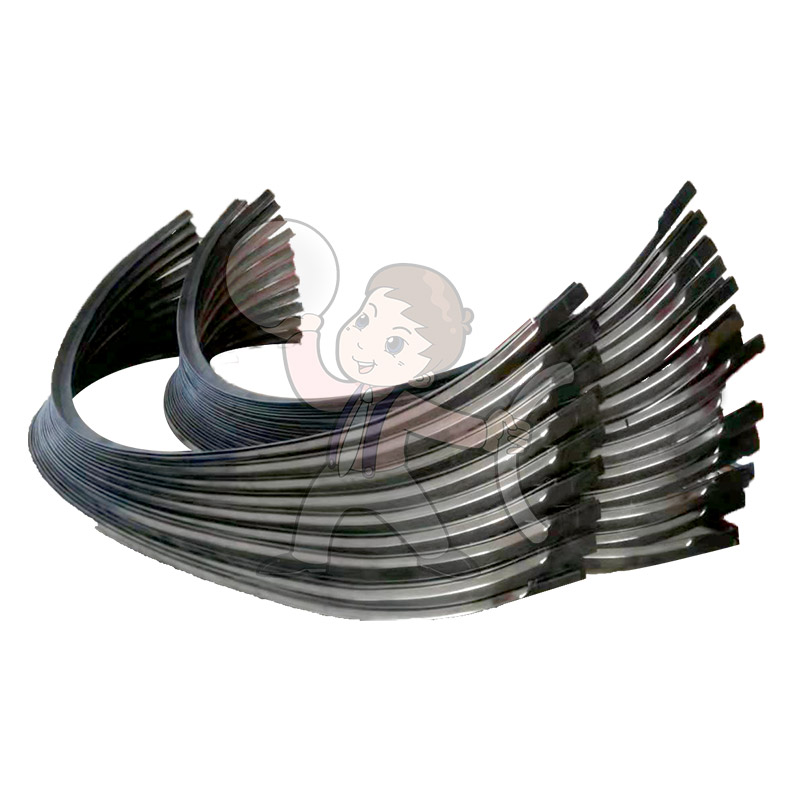

2. Aluminum alloy double curved strip twisted arc for high-speed rail car windows

Automobile making1. Car collision beam:Lightweight car crash beams are made of high-strength steel or aluminum alloy materials, which have excellent strength and toughness, and can withstand huge impact forces during collisions while maintaining structural integrity.

2. Roof luggage rack

3. Ordinary seat frame and chassis

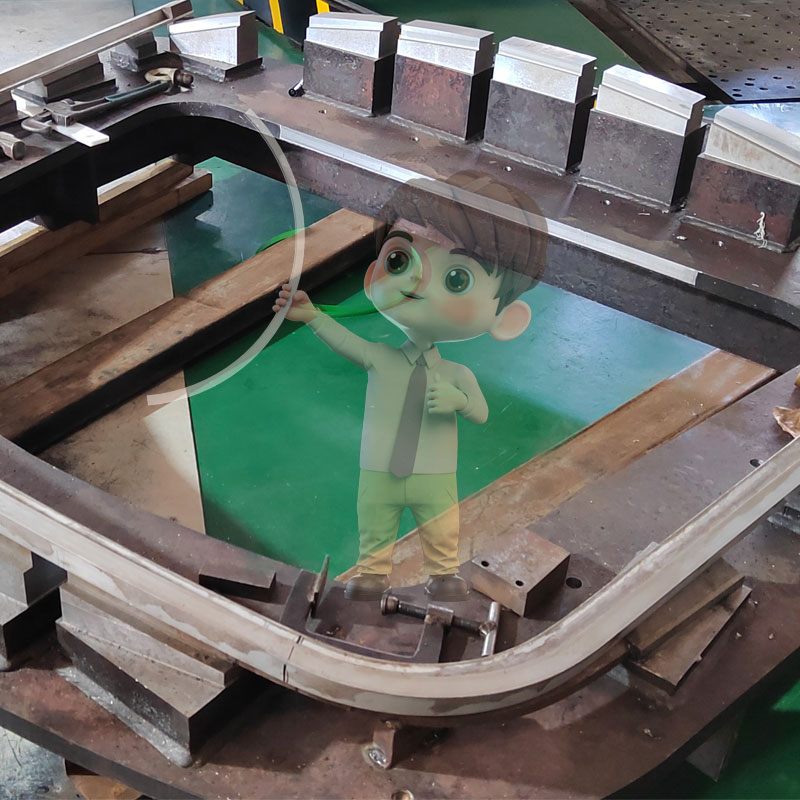

Other transportation equipment1. Special vehicle window frame bending parts

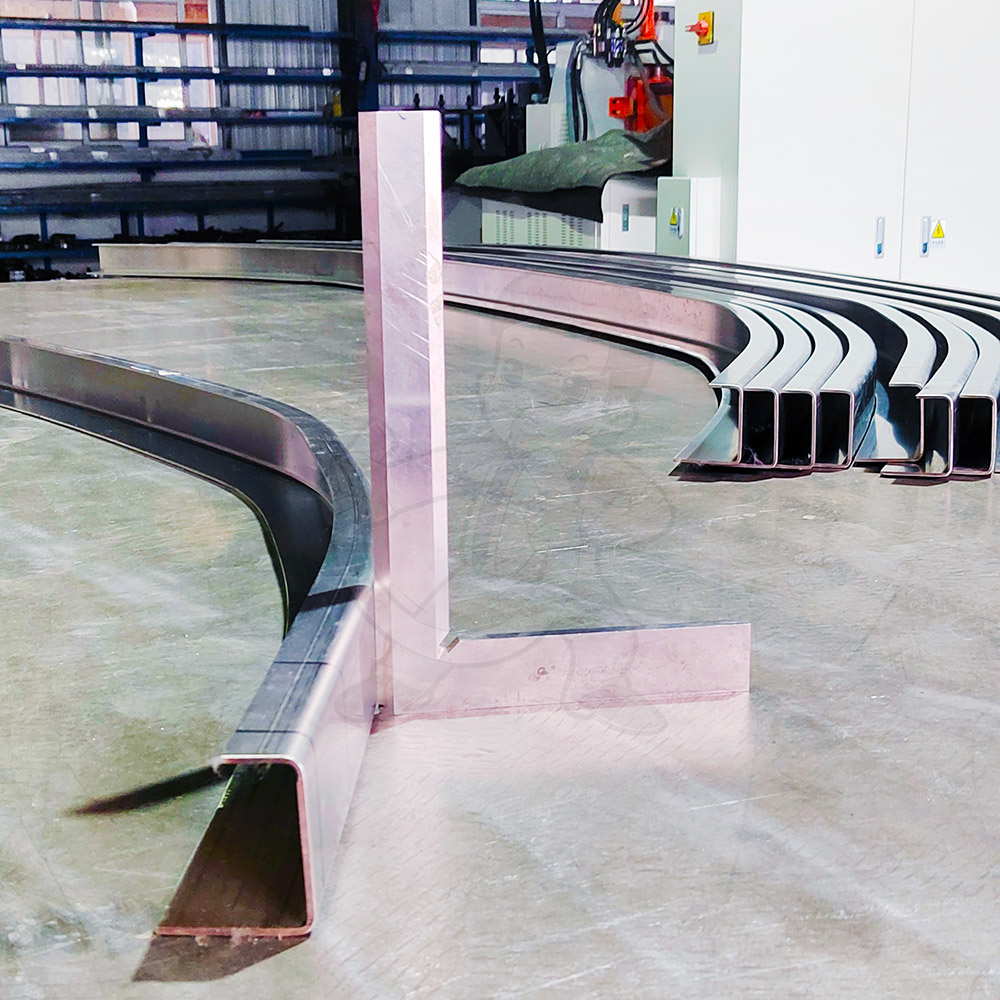

2. Roof curved beam, window pillar, door pillar of rail passenger car

3. Rail passenger car interior handrails

General aviation1. General aircraft landing gear: titanium alloy pipes are usually used for three-dimensional bending, requiring precise bending arc size and external dimensions to ensure the structural strength and stability of the landing gear.

Maritime vessels1. Ship structure and components: Irregular bends are used to manufacture key components such as ship keels, ribs, trusses, and window frames, providing strength and stability to the ship.

2. Pipeline system: The ship's fuel, water supply pipes, sewage discharge pipes, air pipes, power pipes, cooling water pipes, ventilation pipes and other pipelines adopt irregular bends, which have good corrosion resistance and high temperature resistance.

Spinning and weaving1. Curved rail, also known as curved guide rail, is widely used in textile industry automation transmission devices. It seamlessly connects straight rail and straight rail at the turning point, allowing the workpiece to run smoothly and improving transmission efficiency.

Chemical industry1. The pipeline system uses conveying pipelines and steam pipelines to ensure effective material and heat transfer.

2. Heat exchange equipment uses tube bundles and bent pipes to increase contact area and improve heat exchange efficiency.

3. Reinforcement and spray cooling devices are used for storage tanks, with curved arc fittings attached to the tank body to ensure secure welding, and bent pipes used to ensure that the nozzle covers the surface of the tank body, increasing the cooling effect.

Agricultural machinery field1. Agricultural vehicle cab window frame

2. Three point suspension device (fertilizer applicator)

3. Spiral for power rake

4. The roll cage

5. gantry

6. sprayer

Animal husbandry1. Profile bending processing is mainly used for complete milking systems, and special bending equipment is used for cold bending processing.

Medical industrySome medical equipment requires curved fittings to connect pipelines. Mainly used in ventilator tubes, anesthesia machine tubes, medical waste transfer vehicles, medical assistive crutches, patient transfer vehicle bottle guide rails.

English

English Chinese

Chinese Japan

Japan German

German