Metal Bending

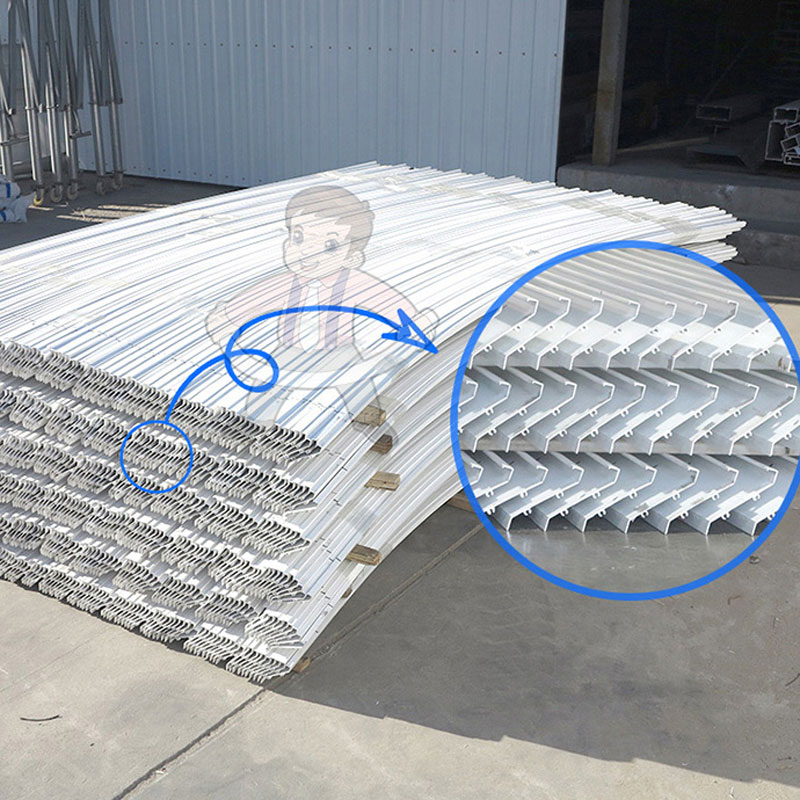

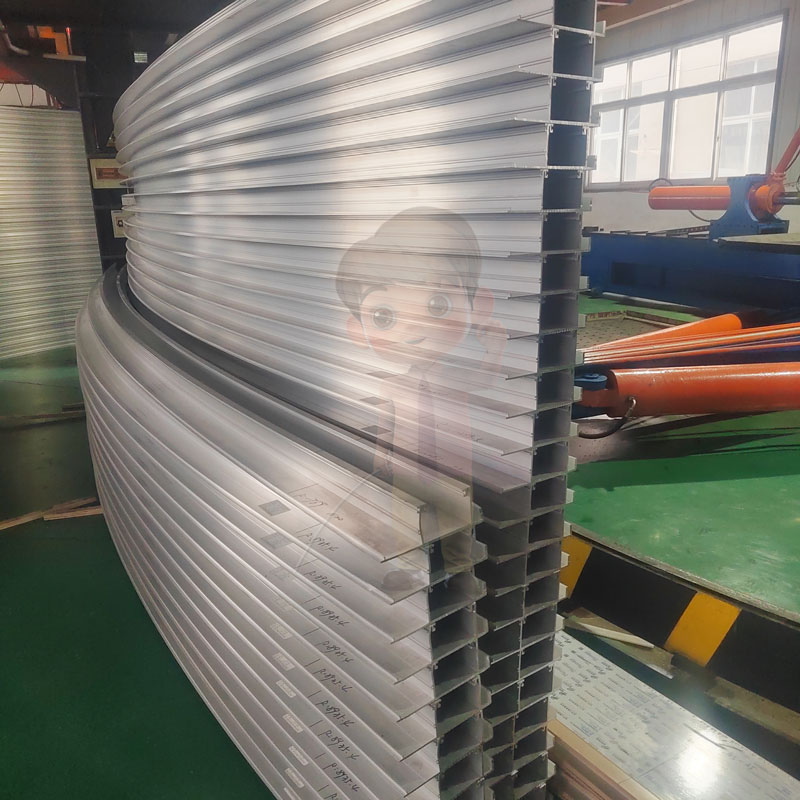

Aluminum Bending Applications

Aluminum profile bending refers to the process of using specialized equipment to bend and process aluminum profiles. This process can bend aluminum profiles into various complex shapes and angles, and is widely used in multiple fields such as construction, transportation, machinery, furniture, etc. Aluminum profiles have become an ideal material choice in many industries due to their excellent physical and chemical properties.

The aluminum profile bending process has become an indispensable part of modern manufacturing due to its unique advantages and wide application prospects. Through reasonable design and processing, aluminum profile bending can meet the growing market demand.

Beijing Shengda Weiye Bending Company offers aluminum bending services for all long sections: bars, structural shapes, pipe and tubing. We can also roll aluminum sheet and plate into cylinders or cylinder segments.

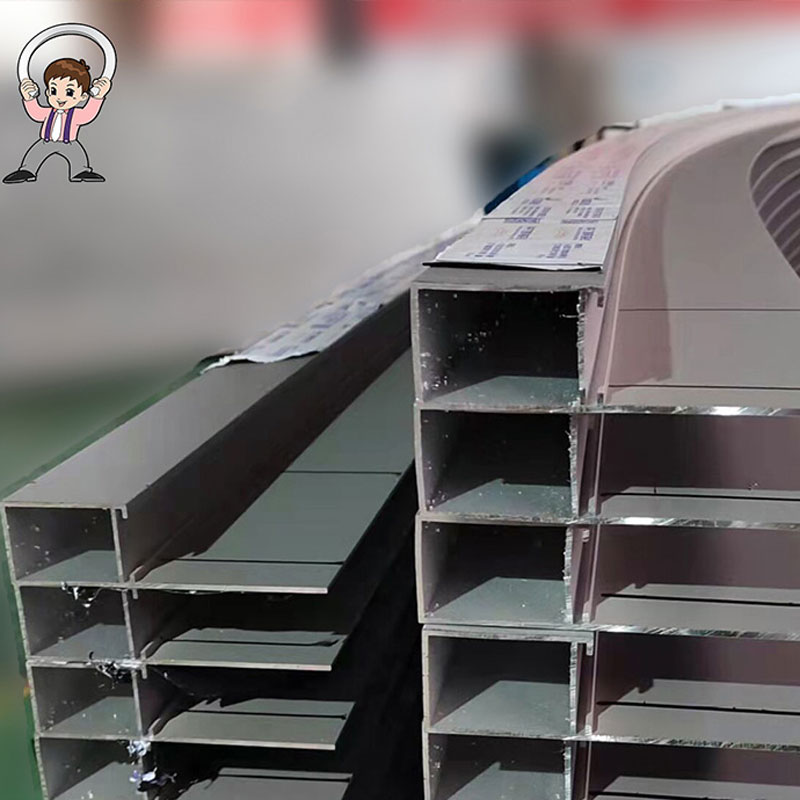

Industrial special profile bending

The bending of industrial profiles is commonly used for specific industrial applications. This process can process profiles into various shapes and sizes to meet specific design and functional requirements. Common applications include mechanical structural components, equipment supports, frames, pipelines, etc.

The bending of industrial profiles has become an indispensable part of modern industrial manufacturing due to its unique advantages and wide application prospects. Through reasonable design, processing, and material selection, products that are efficient, economical, and meet market demand can be achieved.

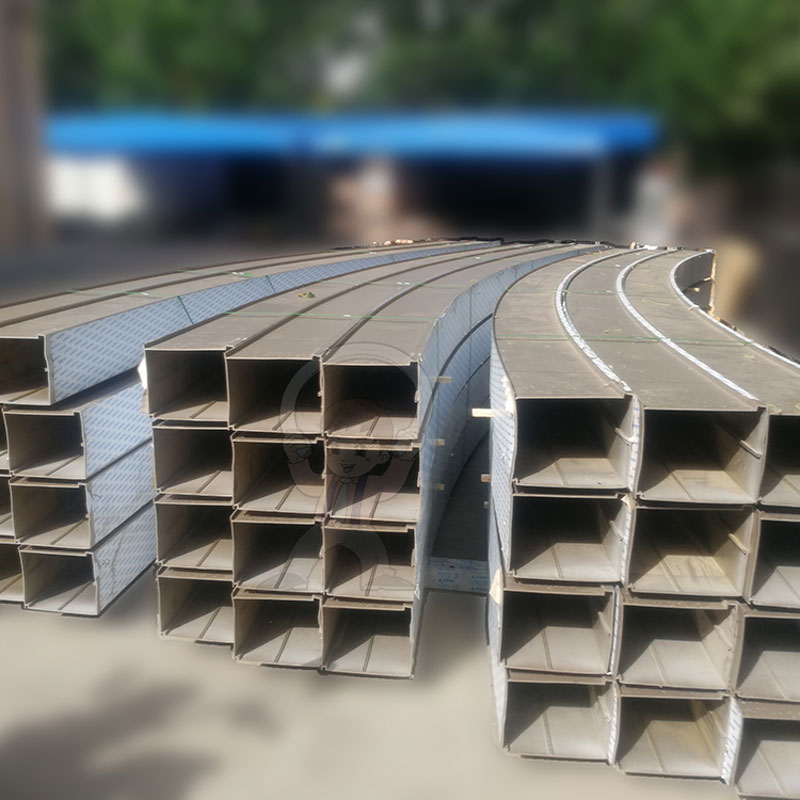

Industrial metal material bending is a process of processing industrial metals into specific shapes through stretching and bending. This process is commonly used for structural components in manufacturing fields such as railway locomotives, automobile manufacturing, other transportation equipment, ships, textiles, chemicals, etc.

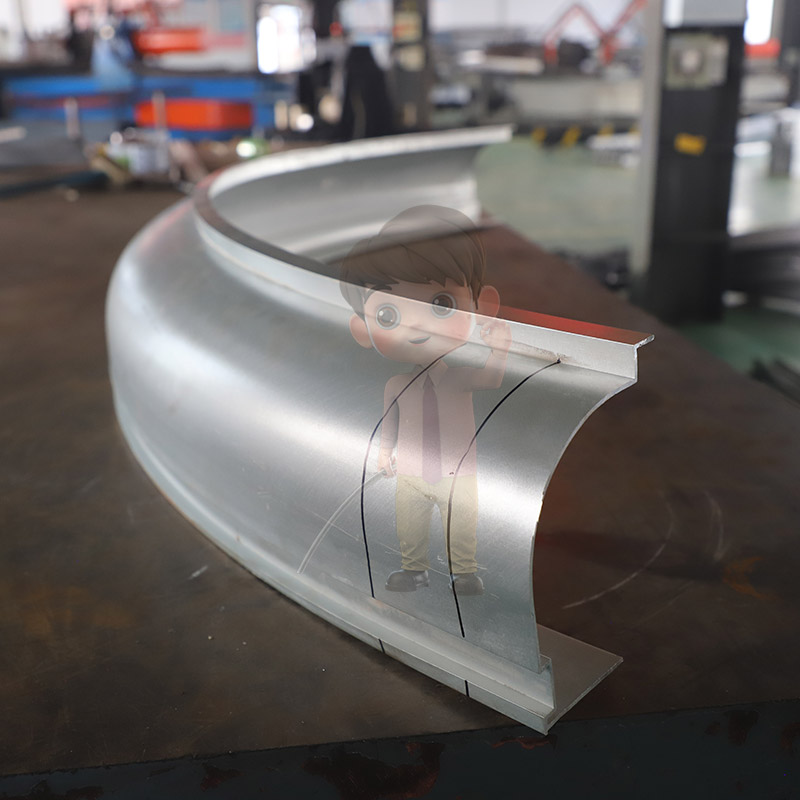

Metal tensile bending

Metal stretching and bending is a metal processing technique mainly used to process metal materials (such as steel, aluminum, copper, etc.) into specific shapes and sizes through stretching and bending.

Metal stretching and bending, as an important metal processing technology, occupies an important position in modern manufacturing industry due to its high efficiency, precision, and flexibility. Through reasonable process design and material selection, the needs of various industries can be effectively met, promoting product innovation and development.

The stretching and bending forming of non industrial metal materials is a common processing technique. This process mainly involves plastic deformation of non industrial metal materials (such as aluminum, copper, magnesium alloys, etc.) along a certain curve or shape by applying external force.

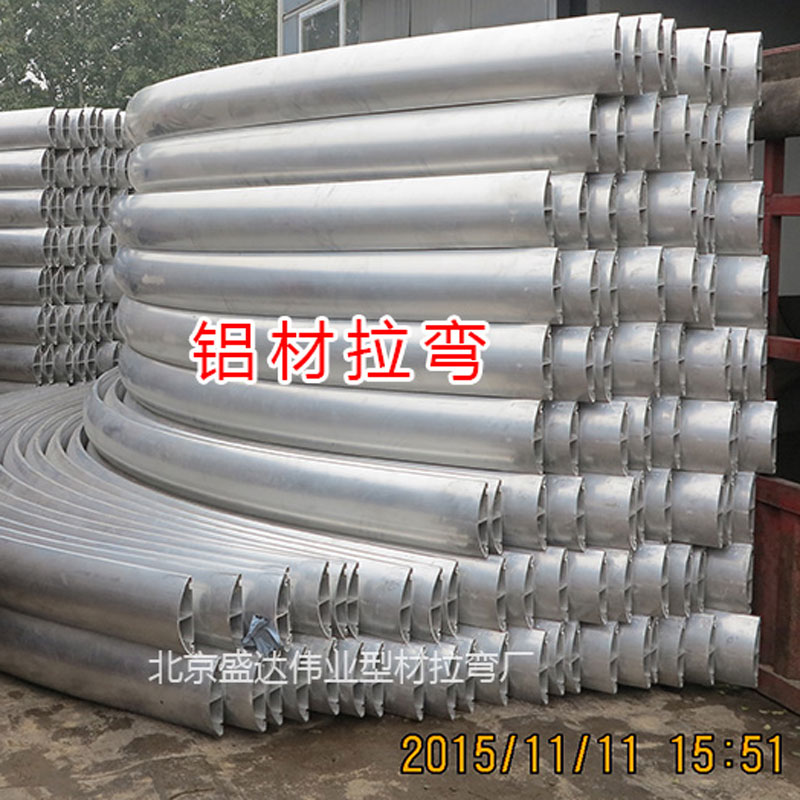

Bending of building materials

Bending of building materials refers to the physical or mechanical processing of building materials to form specific shapes or configurations in the building structure. This technique is widely used in architectural design, especially when aesthetic appearance and structural strength are required.

Bending of metal materials in the construction and decoration industry is a processing method that uses external forces to cause plastic deformation of metal materials, thereby forming the desired shape. It is a high-precision and difficult machining process that requires professional equipment and technical personnel. Before carrying out the bending process, it is necessary to conduct a detailed analysis and design of the material, shape, and dimensions of the irregular aluminum profiles to ensure the feasibility and effectiveness of the bending process.

The bending process of building materials provides greater flexibility and creative space for modern architectural design. Through reasonable design and processing, curved building materials can not only improve the aesthetics and structural strength of buildings, but also effectively utilize materials, reduce costs, and promote the development of sustainable buildings.

English

English Chinese

Chinese Japan

Japan German

German