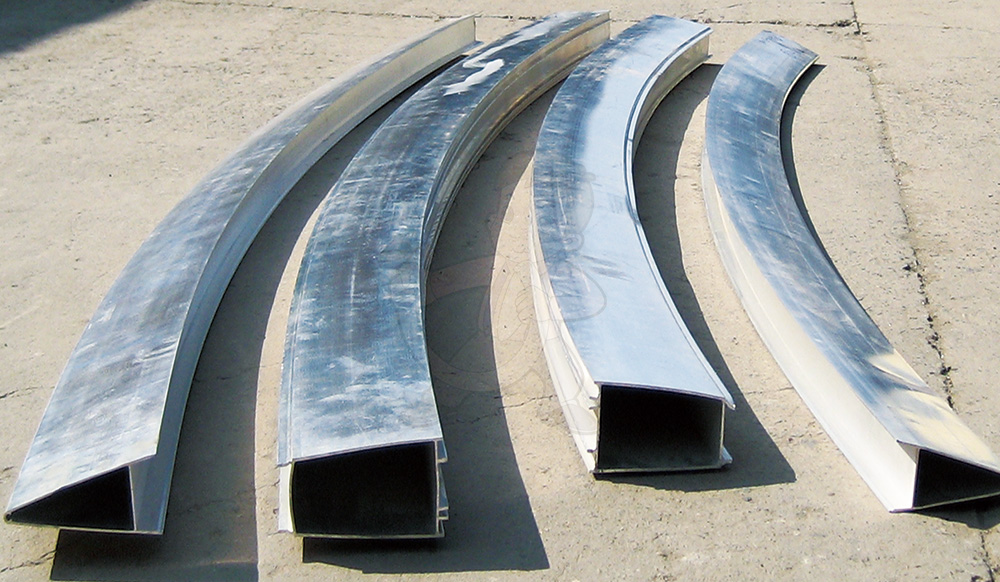

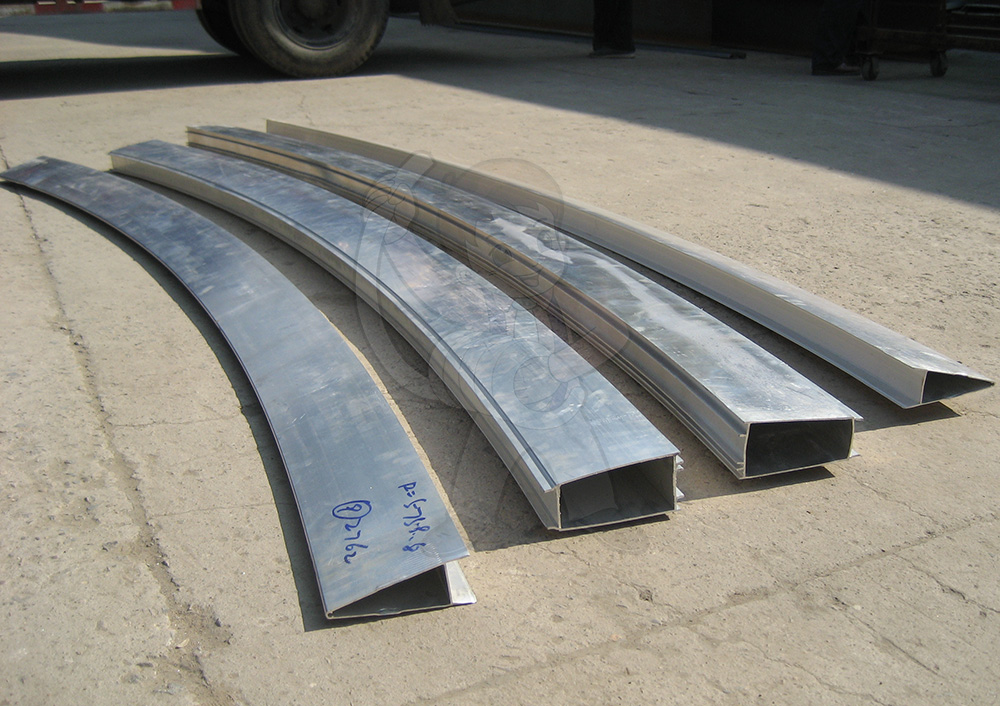

Shuttle shaped louver grille (assembled)

1. The processing difficulty of shuttle shaped sunshade louvers mainly includes the following two points:

A、 Due to its shuttle shaped irregular surface, it is easy for the cross-sectional shape to change during the bending process (difficult to control)

B、 The overall design is composed of four different cross-sectional profiles spliced together. When bending, it is necessary to take into account the dimensional changes caused by the deformation of each profile section, otherwise it is impossible to combine them into a complete shape

2. The scientific researchers and technical workers of Beijing Shengda Weiye Profile Bending Factory have carefully studied and designed unique fixtures and forming molds, which ensure that the cross-sectional deformation of the profile during the bending process is quite small, thereby ensuring minimal size changes. After the bending is completed, it is very convenient for customers to assemble and process, and the joints of the sun visor louvers after splicing are uniform, neat and beautiful, improving the appearance quality of the project.

Engineering Example: Beijing Automotive R&D Base

Leave us a message

English

English Chinese

Chinese Japan

Japan German

German

LIST

LIST