Deep integration of intelligence and automation in industrial bending: Technical innovation to improve production efficiency and product accuracy

In the context of the rapid development of global manufacturing, the application of intelligence and automation technology has become an important driving force to promote industrial upgrading. In recent years, it has actively explored the deep integration of intelligence and automation in the field of industrial bending. By introducing new technologies and equipment, the bending industry not only improves production efficiency, but also significantly improves the accuracy and reliability of products, injecting new vitality into the sustainable development of the local economy.

First, the concept of intelligence and automation

Intelligence usually refers to the use of new technologies such as artificial intelligence, big data and cloud computing to enable devices to make autonomous decisions, learn and adapt to environmental changes. Automation is to replace manual operation by mechanized means to realize the automatic control of the production process. In the bending process, the combination of intelligence and automation can not only improve production efficiency, but also reduce human errors and improve product quality.

Second, the analysis of the current situation of the bending industry

The industrial bending industry mainly involves the processing of metal profiles, pipes and other products. These products are widely used in many fields such as construction, transportation and furniture. The traditional bending process often relies on manual operation, which leads to low production efficiency and difficulty in ensuring accuracy. With the increasing market demand, enterprises are facing the pressure of transformation and upgrading.

Third, the application of intelligence and automation technology

1. Introduction of intelligent equipment

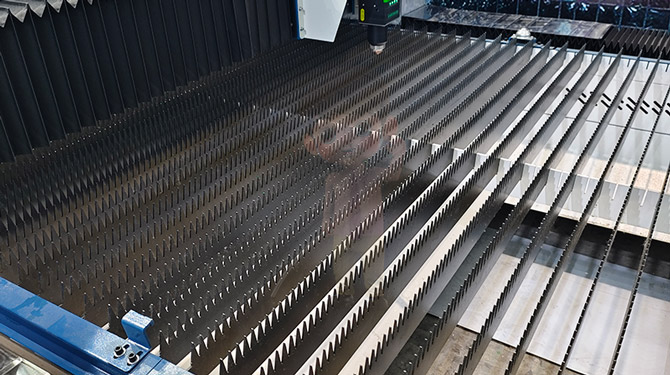

Bending enterprises gradually introduce new intelligent equipment, such as CNC bending machine. These devices are controlled by computer programs to achieve precise adjustment of parameters such as bending Angle and radius. In addition, the application of smart sensors enables the equipment to monitor the production status in real time and adjust the process parameters in time, thus ensuring product quality.

2. Data-driven production management

Through big data analysis, enterprises can monitor and analyze various data in the production process in real time. For example, the running status of machines, the consumption of raw materials, etc. during the production process can be recorded and analyzed. According to the results of data analysis, enterprises can optimize production processes, reduce resource waste and improve production efficiency.

3. Intelligent production scheduling system

Bending enterprises have also introduced intelligent production scheduling system. The system can automatically make production plans according to order requirements, production capacity and other factors, so as to optimize resource allocation. Through intelligent scheduling, enterprises are able to respond to market changes faster and improve delivery efficiency.

4. Automatic testing and quality control

Product quality control is very important in tensile and bending process. Traditional quality inspection often relies on manual work, which has certain errors. Nowadays, enterprises have realized the comprehensive monitoring of product quality by introducing automated testing equipment. These devices use laser ranging, image recognition and other technologies to detect each product with high precision to ensure that it meets the design requirements.

Fourth, the benefits brought by technology integration

1. Improve production efficiency

Through the deep integration of intelligence and automation, bending enterprises have greatly improved production efficiency. The production tasks that used to require multiple workers can now be completed in a shorter time through the automation of smart devices, and the production capacity has been significantly improved.

2. Improve product accuracy

The precise control of intelligent equipment makes the bending Angle and radius of the product more accurate, and reduces the error in the production process. The introduction of automatic detection system enables enterprises to carry out strict quality control in every link of production, and ensure that the pass rate of the final product is greatly improved.

3. Reduce production costs

Although the introduction of intelligent and automated equipment requires a certain initial investment, in the long run, enterprises can significantly reduce the overall production cost by improving production efficiency, reducing labor costs and material waste. This enables enterprises to occupy a more favorable position in the market competition.

4. Enhance market competitiveness

With the improvement of product quality and production efficiency, the competitiveness of bending enterprises in the market has been significantly enhanced. It can meet the needs of customers more quickly and flexibly, making enterprises stand out in the fierce market environment.

V. Prospects for future development

Looking forward to the future, the bending industry will continue to move forward on the road of intelligence and automation. With the continuous progress of technology, enterprises will have the opportunity to further improve production efficiency and product accuracy. At the same time, policy support and market demand will also promote the rapid development of this field.

In this process, enterprises need to constantly increase investment in research and development and cultivate professionals to adapt to the continuous development of intelligence and automation. In addition, bending enterprises should also strengthen cooperation and exchange between industries, jointly explore new models of intelligent manufacturing, and form a good industrial ecology.

It has also played a positive role in promoting industrial transformation and upgrading. In recent years, the government has issued a series of policies to encourage enterprises to introduce new intelligent and automated equipment, and to provide financial support and technical guidance. These policies provide a good external environment for the technological innovation of enterprises.

In addition, the involvement of industry associations and research institutions is crucial. Through cooperation with universities and research institutions, enterprises can obtain the latest technology and management ideas, and promote the application and promotion of technology. At the same time, industry associations can organize technical exchange meetings to share successful experiences and promote cooperation and synergy among enterprises.

The deep integration of intelligence and automation technology is reshaping the industrial bending industry, improving production efficiency and product accuracy, and injecting new impetus for the sustainable development of enterprises. Facing the future, bending enterprises need to actively respond to challenges, seize opportunities, and constantly promote technological innovation and management optimization to ensure a position in the fierce market competition.

Through policy support, industry coordination and the efforts of enterprises themselves, the bending industry will usher in a brighter development prospect and contribute more substantial strength to the development of local economy. With the continuous progress of intelligence and automation technology, the future bending industry will be more efficient, intelligent and green, and become an important part of the national and even global manufacturing industry.

23

2025-04

Number of visitors:1

HOT NEWS

-

Precision Hot Bending Solutions for Custom Metal Profiles

2026-02-13

-

Concentric frequency with growth: Sheng Dara bend to build a shared happiness

2026-02-04

-

Precision and Efficiency in Plastic Steel Bending: Key Techniques and Benefits

2026-01-26

-

High-Precision C-Channel Steel Bending Solutions for Customized Structural and Architectural Applications

2026-01-16

English

English Chinese

Chinese Japan

Japan German

German

LIST

LIST